- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Why Is a Gate Valve Not Suitable for Throttling Flow

For over two decades in the tech world, I've learned that the best solutions come from using tools exactly as they were designed. You wouldn't use a screwdriver to hammer a nail, right The same principle is profoundly true in industrial fluid systems. One of the most common misconceptions I've encountered, from plant floors to engineering discussions, is the use of a Gate Valve for controlling flow rate. Today, I want to draw on my experience and explain, in detail, why this practice is not just inefficient but can be detrimental to your entire system.

What Is the Primary Design Purpose of a Gate Valve

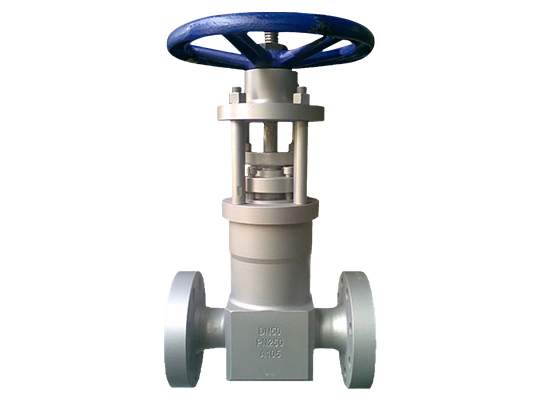

A Gate Valve is a masterpiece of simplicity and brute force. Its name says it all: it functions like a gate in a wall. The core component is a flat, wedge-shaped, or parallel-faced gate that moves perpendicularly into and out of the path of the flow. When the handwheel is turned to open the valve, the gate lifts completely, creating an unobstructed, full-bore opening. This means the flow path is as wide as the pipe itself, resulting in minimal pressure drop when fully open. Conversely, when closed, the gate seats firmly against the valve body, providing a tight shut-off.

The design intent is binary: fully open or fully closed. It's designed for isolation, not for modulation. Think of it as an on/off switch for your pipeline. Now, let's contrast this with what happens when we try to use it for a job it wasn't built for.

What Happens When You Use a Gate Valve for Throttling

When you leave a Gate Valve in a partially open position to reduce flow, you invite a host of problems. The design features that make it excellent for isolation become its Achilles' heel in throttling applications.

-

Rapid Seat and Disc Erosion: The gate and the seats (the surfaces it seals against) are designed to make full contact only in the fully closed position. In a partially open state, the high-velocity flow passes only through the narrow gap between the gate and the seats. This creates a high-velocity, turbulent jet that continuously blasts the seating surfaces. This erodes the material—whether it's metal, or resilient material—leading to premature failure and the valve's inability to seal tightly when needed.

-

Vibration and Cavitation: The turbulent flow caused by the partially open gate can lead to severe vibration. This not only damages the valve itself but can also transmit harmful vibrations throughout the piping system. Furthermore, if the pressure drop is significant, it can cause cavitation—the formation and implosion of vapor bubbles—which literally chips away at the metal components with immense force.

-

Stem and Actuator Damage: The stem, which connects the handwheel to the gate, is under tremendous lateral stress in a partially open position due to the unbalanced forces of the flowing fluid. This can lead to stem bending, galling (a form of wear), and premature failure of the packing, causing leaks. If the valve is automated, the actuator will struggle against these forces, leading to motor burnout or pneumatic system failure.

To put it simply, using a Gate Valve for throttling is a surefire way to shorten its lifespan, compromise your system's safety, and increase maintenance costs. It's a classic case of the wrong tool for the job.

How Does a LYV® Gate Valve Ensure Long-Term Reliability in Isolation Services

At LYV®, we engineer our valves with a clear understanding of their intended application. Our isolation Gate Valves are built to perform one job perfectly: providing a bubble-tight seal in the closed position and minimal flow resistance in the open position. We achieve this through precision manufacturing and superior materials that withstand the test of time, even in the harshest environments. When you use a LYV® Gate Valve strictly for on/off duty, you are investing in decades of reliable, maintenance-free service.

To help you make an informed decision, let's compare the key parameters of a valve designed for isolation versus one designed for throttling.

Key Parameters for Valve Selection

| Parameter | Isolation Valve (e.g., Gate Valve) | Throttling Valve (e.g., Globe Valve) |

|---|---|---|

| Primary Function | On/Off Control | Flow Rate Regulation |

| Flow Path | Straight-Through, Full Bore | Tortuous (S-shaped) Path |

| Pressure Drop | Very Low (when fully open) | Inherently High |

| Sealing Mechanism | Flat or Wedge Gate against parallel seats | Plug against a contoured seat ring |

| Suitable Position | Fully Open or Fully Closed | Any position between open and closed |

This table highlights the fundamental design differences. But what does this mean in terms of hard numbers and specifications for your system? The following table outlines critical design and material considerations for our LYV® Gate Valves to ensure they meet your isolation needs.

LYV® Premium Industrial Gate Valve Specifications (Sample)

| Feature | Specification | Benefit to Your Operation |

|---|---|---|

| Body & Bonnet Material | ASTM A216 WCB Carbon Steel | Excellent strength and durability for high-pressure, high-temperature services. |

| Trim Material (Seat/Disc) | 13% Chrome Stainless Steel | Provides superior erosion and corrosion resistance, ensuring a tight seal over thousands of cycles. |

| Seat Design | Flexible Wedge | Minimizes sticking due to temperature fluctuations and provides superior sealing. |

| Stem Material | ASTM A182 F6a Stainless Steel | High resistance to galling and corrosion, ensuring smooth operation and long service life. |

| Pressure Rating | ANSI Class 150 to 2500 | Designed to meet the demands of your specific application pressure. |

| End Connection | Flanged (RF), Socket Weld, Butt Weld | Versatile connections to suit your piping design requirements. |

Gate Valve FAQ Common Questions

Over the years, I've fielded countless questions. Here are some of the most frequent ones, answered in detail.

What is the main advantage of a gate valve over a ball valve

While ball valves are excellent for quick quarter-turn operation, a well-designed Gate Valve like those from LYV® often provides a more robust seal for high-pressure, high-temperature applications, especially in larger pipe sizes. The parallel or wedge-shaped gate provides a larger sealing surface area, which can handle thermal expansion better and offer a more leak-tight closure in demanding services over a long period.

Can a gate valve be installed in any direction

This is a critical question. Generally, most Gate Valve designs are bidirectional. However, for optimal performance and ease of operation, it is recommended to install the valve with the stem upright. This is particularly important for LYV® valves with an Outside Screw & Yoke (OS&Y) design, where the stem threads are kept outside of the flow path, preventing corrosion and ensuring smooth operation. Always consult the manufacturer's installation guide, which for LYV® valves, provides clear, step-by-step instructions.

How often should a gate valve be maintained if used correctly

When used strictly as an isolation valve (either fully open or fully closed), a LYV® Gate Valve requires minimal maintenance. We recommend a periodic operational check, typically annually, which involves cycling the valve from fully open to fully closed and back again. This helps ensure the stem and seats remain free of debris and corrosion. The packing may need occasional adjustment if a leak is detected. Our LYV® valves are built for longevity, but regular checks are the key to maximizing service life, which can easily extend to 20 years or more with proper care.

What Is the Correct Valve to Use for Throttling Flow

If you need to control flow rate, you should be looking at valves specifically designed for that purpose. The most common and effective choice is a Globe Valve. Its design features a plug and seat arrangement that allows for precise control of flow with minimal damage to the components. Other excellent options include butterfly valves for larger lines or control valves with specialized trim and actuators for fully automated processes. The team at LYV® also offers a range of these throttling-specific valves, engineered with the same commitment to quality and durability. Choosing the right valve not only ensures process efficiency but also protects your capital investment.

Ready to Specify the Right Valve for Your System

Understanding the distinct roles of different valves is the foundation of a safe, efficient, and cost-effective operation. Using a Gate Valve for throttling is a costly mistake, but it's an entirely avoidable one. By selecting the right tool for the job—a robust LYV® Gate Valve for reliable isolation, or a precision LYV® control valve for accurate throttling—you ensure the integrity and longevity of your fluid systems.

Don't leave your valve selection to chance. Let our experienced engineers help you make the perfect choice.

Contact us today for a free consultation and let LYV® be your partner in engineering reliability. We'll help you analyze your application and recommend the ideal valve solution.