- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

What Is a Trunnion Mounted Ball Valve and Why Does It Matter in Industrial Flow Control?

2025-12-25

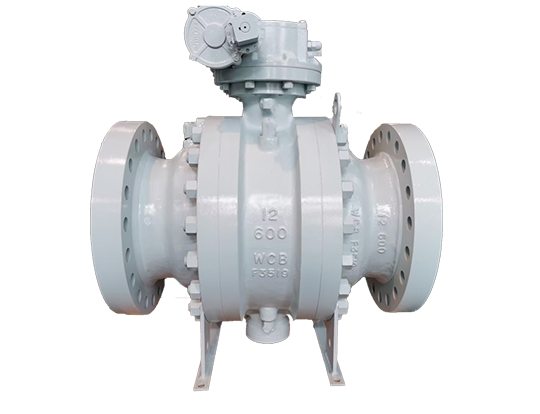

Trunnion mounted ball valves play a critical role in modern industrial flow control systems, particularly in high-pressure, large-diameter, and long-distance pipeline applications. Compared with floating ball valves, this valve type offers superior stability, reduced operating torque, and enhanced sealing reliability. As industries such as oil and gas, petrochemical processing, LNG, and power generation continue to demand higher safety and efficiency standards, understanding the structure, performance, and selection logic of trunnion mounted ball valves becomes increasingly important.

Article Summary

This comprehensive guide explains what a trunnion mounted ball valve is, how it works, why it outperforms traditional floating ball valves in demanding conditions, and which factors should be considered when selecting one. The article also covers applications, standards, materials, maintenance, and frequently asked questions, following Google EEAT principles and professional industrial valve practices.

Table of Contents

- What Is a Trunnion Mounted Ball Valve?

- How Does a Trunnion Mounted Ball Valve Work?

- Why Is a Trunnion Mounted Ball Valve More Stable?

- What Are the Key Structural Components?

- Which Industries Use Trunnion Mounted Ball Valves?

- How Does It Compare with Floating Ball Valves?

- What Materials and Standards Are Commonly Used?

- How to Select the Right Trunnion Mounted Ball Valve?

- Frequently Asked Questions

What Is a Trunnion Mounted Ball Valve?

A trunnion mounted ball valve is a type of quarter-turn valve in which the ball is mechanically anchored by trunnions (shaft supports) at both the top and bottom. Unlike floating ball valves, the ball does not move under pressure. Instead, the seats move toward the ball to achieve sealing.

This design significantly reduces friction between the ball and seats, making trunnion mounted ball valves ideal for high-pressure, large-bore pipeline systems. They are widely manufactured by professional valve suppliers such as Zhejiang Liangyi Valve Co., Ltd., ensuring compliance with international standards and long-term operational reliability.

How Does a Trunnion Mounted Ball Valve Work?

The working principle of a trunnion mounted ball valve is based on a fixed ball structure combined with spring-loaded or pressure-assisted seats. When the valve is closed, line pressure pushes the upstream seat against the ball, ensuring tight sealing. The downstream seat may be spring-energized to maintain sealing even at low pressure.

- The ball is fixed in position by upper and lower trunnions

- Valve seats move axially to seal against the ball

- Operating torque remains low regardless of pressure

- Double block and bleed (DBB) functionality is often available

This mechanism ensures smooth operation, reduced wear, and consistent sealing performance over long service cycles.

Why Is a Trunnion Mounted Ball Valve More Stable?

Stability is one of the most significant advantages of trunnion mounted ball valves. Because the ball is mechanically supported, it does not shift under fluctuating pressure or temperature conditions.

Key stability benefits include:

- Minimal deformation under high pressure

- Lower stress on sealing surfaces

- Extended seat and ball lifespan

- Reliable operation in critical shut-off applications

These features make trunnion mounted ball valves especially suitable for safety-critical systems such as transmission pipelines and emergency shut-down systems.

What Are the Key Structural Components?

A trunnion mounted ball valve consists of several precision-engineered components that work together to ensure performance and durability.

| Component | Function |

|---|---|

| Ball | Controls flow by rotating 90 degrees |

| Trunnion Shaft | Supports the ball and absorbs pressure load |

| Valve Seats | Provide tight sealing against the ball |

| Body and Bonnet | Contain pressure and connect to the pipeline |

| Stem | Transmits torque from actuator or handle |

Which Industries Use Trunnion Mounted Ball Valves?

Due to their robust design and sealing reliability, trunnion mounted ball valves are widely used across multiple industries.

- Oil and gas transmission pipelines

- Petrochemical and chemical processing plants

- LNG and cryogenic systems

- Power generation facilities

- Water injection and high-pressure utilities

Many of these applications require compliance with standards such as API 6D and ISO 17292, which are commonly followed by manufacturers like Zhejiang Liangyi Valve Co., Ltd.

How Does It Compare with Floating Ball Valves?

Understanding the difference between trunnion mounted and floating ball valves helps engineers choose the correct solution.

| Feature | Trunnion Mounted Ball Valve | Floating Ball Valve |

|---|---|---|

| Ball Support | Fixed by trunnions | Free-floating |

| Operating Torque | Low and stable | Increases with pressure |

| Application Size | Medium to large diameter | Small to medium diameter |

| Pressure Rating | High pressure | Moderate pressure |

What Materials and Standards Are Commonly Used?

Material selection depends on the operating medium, temperature, and pressure. Common materials include:

- Carbon steel (WCB, A105)

- Stainless steel (CF8, CF8M)

- Alloy steel for high-temperature service

Trunnion mounted ball valves are typically designed and tested according to recognized standards such as API 6D, API 608, ISO 14313, and ASME B16.34. These standards ensure safety, interchangeability, and long-term reliability.

For additional guidance on valve standards, see this industrial valve standard overview.

How to Select the Right Trunnion Mounted Ball Valve?

Selecting the correct valve requires a systematic evaluation of operating conditions and system requirements.

- Define pressure and temperature range

- Identify media characteristics

- Confirm size and connection type

- Check required certifications and standards

- Evaluate automation and actuation needs

Working with an experienced manufacturer such as Zhejiang Liangyi Valve Co., Ltd. helps ensure proper selection, customization, and after-sales support.

Frequently Asked Questions

What is the main advantage of a trunnion mounted ball valve?

The main advantage is reduced operating torque and enhanced sealing stability, especially in high-pressure and large-diameter pipeline systems.

How does a trunnion mounted ball valve achieve sealing?

Sealing is achieved through pressure-assisted or spring-loaded seats that move toward a fixed ball, ensuring tight shut-off under varying pressures.

Why are trunnion mounted ball valves preferred in oil and gas pipelines?

They offer high reliability, double block and bleed capability, and stable performance over long transmission distances.

Which standards apply to trunnion mounted ball valves?

Common standards include API 6D, ISO 14313, API 608, and ASME B16.34, depending on application requirements.

How long is the service life of a trunnion mounted ball valve?

With proper material selection and maintenance, these valves can operate reliably for decades in demanding industrial environments.