- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How Does A Resilient Seated Gate Valve Function

2025-09-10

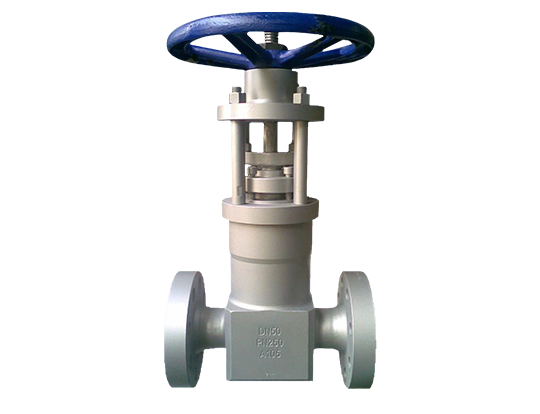

Have you ever wondered what makes certain water systems so reliable while others constantly face leakage issues? As someone who has worked with fluid control systems for over two decades, I’ve seen firsthand how the right Gate Valve can transform operational efficiency. Today, I want to break down exactly how a resilient seated Gate Valve functions and why it might be the solution you’ve been searching for.

What Is a Resilient Seated Gate Valve

A resilient seated Gate Valve is designed with an elastomeric seal—usually made from materials like EPDM or NBR—mounted on the gate. When the valve closes, this seal compresses against the valve body, creating a bubble-tight shut-off. Unlike metal-seated valves, the resilient seat adapts to minor imperfections in the sealing surface, which greatly reduces the risk of leakage. This is especially valuable in water and wastewater applications where preventing fluid loss is critical.

How Does the Sealing Mechanism Work

The magic of this Gate Valve lies in its sealing mechanism. When you rotate the handwheel, the stem moves the gate downward. As it approaches the closed position, the gate compresses the resilient seat against the valve body. This compression creates a secure, leak-proof seal without requiring excessive torque. The flexibility of the seat material ensures that even if there’s debris or slight wear, the seal remains effective. Isn’t it frustrating when valves fail due to minor debris? That’s where the resilience truly shines.

What Are the Key Features of LYV® Resilient Seated Gate Valves

At LYV®, we’ve engineered our valves based on years of field feedback. Here’s what sets our Gate Valve apart:

-

Body Material: Ductile iron with epoxy coating for corrosion resistance.

-

Seat Material: High-quality EPDM or NBR, suitable for potable water.

-

Pressure Rating: PN16/PN25, capable of handling standard water system pressures.

-

Temperature Range: -10°C to 70°C for EPDM seats, and -10°C to 80°C for NBR.

-

End Connections: Flanged ends compliant with EN 1092-2 standards.

To give you a clearer picture, here’s a table comparing standard features with LYV®’s enhancements:

| Feature | Standard Valve | LYV® Valve |

|---|---|---|

| Seat Material | Generic EPDM | Certified EPDM/NBR |

| Pressure Rating | PN16 | PN16/PN25 |

| Corrosion Protection | Basic coating | Advanced epoxy coating |

| Operational Life | ~5,000 cycles | Over 10,000 cycles |

Why Choose LYV® for Your Gate Valve Needs

I’ve personally seen countless systems upgraded with LYV® valves, and the difference is measurable. Our valves are designed not just to meet standards, but to exceed expectations. The reinforced seat design and robust stem construction mean fewer maintenance interruptions. For those tired of frequent replacements, our Gate Valve offers longevity that translates into cost savings.

Where Should You Use a Resilient Seated Gate Valve

These valves are ideal for water distribution, wastewater treatment, and irrigation systems. Their ability to provide a tight seal even in dirty water conditions makes them a go-to choice for municipal and industrial applications. If you’re dealing with potable water, the certified materials in LYV® valves ensure compliance with health standards.

How Can You Extend the Life of Your Gate Valve

Regular maintenance is key. Periodically cycle the valve to prevent seizing, and ensure the system is flushed to remove debris. With LYV® valves, the maintenance intervals are longer thanks to the durable design, but simple checks will keep everything running smoothly.

After two decades in this industry, I can confidently say that choosing the right valve makes all the difference. At LYV®, we’ve poured our expertise into every product to ensure you get reliability without compromise. If you’re looking for a Gate Valve that combines innovative design with proven performance, reach out to us today. Contact us to discuss your specific needs and discover how LYV® can solve your fluid control challenges.