- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

What Makes Gate Valves Essential for Industrial Applications?

Gate valves are one of the most widely used valves in industrial piping systems. They play a critical role in regulating the flow of liquids and gases, ensuring that industrial processes operate efficiently and safely. Companies like Zhejiang Liangyi Valve Co., Ltd. specialize in producing high-quality gate valves that meet rigorous standards for performance, durability, and reliability.

Table of Contents

- What is a Gate Valve?

- What are the Different Types of Gate Valves?

- How Does a Gate Valve Work?

- Which Industries Use Gate Valves?

- How to Choose the Right Gate Valve?

- Why is Gate Valve Maintenance Important?

- FAQ About Gate Valves

- References

What is a Gate Valve?

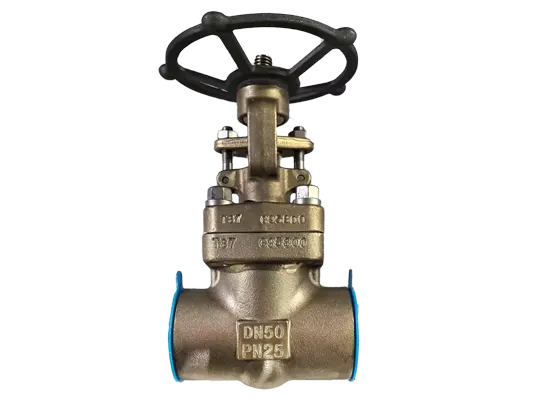

A gate valve is a type of valve that uses a flat or wedge-shaped gate to control the flow of fluid. When the valve is fully open, the gate is completely lifted out of the flow path, providing minimal resistance. When closed, the gate fits snugly into the valve seat, stopping the flow completely. This makes gate valves ideal for on/off control in pipelines.

Key Features of Gate Valves

- Linear motion for precise opening and closing

- Minimal pressure drop when fully open

- Available in a variety of materials including stainless steel, carbon steel, and bronze

- Suitable for high-pressure and high-temperature applications

What are the Different Types of Gate Valves?

Gate valves come in multiple designs to meet different industrial requirements. Choosing the right type depends on fluid type, pressure, temperature, and installation preferences.

| Type | Description | Applications |

|---|---|---|

| Rising Stem Gate Valve | The stem rises as the gate is lifted. Easy to visually check if valve is open or closed. | Water treatment, oil pipelines, and power plants |

| Non-Rising Stem Gate Valve | The stem does not rise; the gate moves within the valve body. Suitable for limited space installations. | Industrial pipelines, chemical plants |

| Knife Gate Valve | Designed for slurries and thick liquids, with a sharp-edged gate to cut through fluids. | Pulp & paper, mining, wastewater |

| Cast vs. Forged Gate Valves | Cast valves are economical, while forged valves offer higher strength and pressure tolerance. | Oil & gas, chemical industries |

How Does a Gate Valve Work?

Gate valves operate using a simple principle: lifting a gate vertically to allow fluid flow and lowering it to stop flow. The operation can be manual via a handwheel or automated with actuators. The wedge-shaped gate ensures a tight seal, even under high pressure.

Step-by-Step Operation:

- Turn the handwheel clockwise to lower the gate.

- The gate presses against the seat, stopping fluid flow.

- Turn the handwheel counterclockwise to lift the gate.

- Fluid passes through with minimal obstruction.

Automated gate valves use electric, pneumatic, or hydraulic actuators, allowing remote operation in complex systems.

Which Industries Use Gate Valves?

Gate valves are highly versatile and are used in a wide range of industries:

- Oil & Gas: Control crude oil, refined products, and natural gas pipelines.

- Water Treatment: Manage clean water and wastewater pipelines.

- Chemical & Petrochemical: Handle corrosive fluids and high-pressure systems.

- Power Plants: Steam, cooling water, and fuel pipelines.

- Mining & Slurry Transport: Knife gate valves manage abrasive slurries efficiently.

Zhejiang Liangyi Valve Co., Ltd. provides solutions tailored for these industries, ensuring valves meet pressure, temperature, and corrosion-resistance requirements.

How to Choose the Right Gate Valve?

Choosing the right gate valve requires careful consideration of several factors:

| Factor | Consideration |

|---|---|

| Material | Stainless steel for corrosion resistance, carbon steel for strength. |

| Pressure Rating | Ensure valve rating matches pipeline operating pressure. |

| Size | Match valve size with pipeline diameter for efficient flow. |

| Type | Rising stem for visual status; knife gate for slurries. |

| Operation | Manual or automated depending on accessibility and control requirements. |

Why is Gate Valve Maintenance Important?

Regular maintenance ensures long service life and prevents costly downtime. Key maintenance practices include:

- Lubricating the stem and gate to reduce friction.

- Inspecting seals and seats for wear.

- Testing valve operation periodically to ensure proper opening and closing.

- Cleaning deposits or debris from the valve body, especially for slurry applications.

Zhejiang Liangyi Valve Co., Ltd. also offers maintenance services and replacement parts, ensuring their valves operate efficiently for decades.

FAQ About Gate Valves

Q1: What is the main difference between gate valves and globe valves?

A1: Gate valves provide minimal flow resistance when fully open and are mainly used for on/off control. Globe valves allow precise flow regulation but create higher pressure drop.

Q2: Can gate valves be used for throttling?

A2: No, gate valves are designed for fully open or fully closed positions. Throttling can cause seat damage and vibration.

Q3: How does a knife gate valve differ from a standard gate valve?

A3: Knife gate valves have a sharp-edged gate for cutting through viscous fluids or slurries. Standard gate valves are better for clean liquids or gases.

Q4: How often should a gate valve be maintained?

A4: Maintenance depends on operating conditions. For standard industrial applications, a yearly inspection is recommended, while slurry pipelines may require more frequent checks.

Q5: Why choose Zhejiang Liangyi Valve Co., Ltd. for gate valves?

A5: They offer high-quality, durable gate valves with a wide range of materials and designs, backed by decades of engineering expertise and customer support.

References

- Engineering Toolbox: Gate Valves

- Valve Magazine

- Industrial Valves Overview

- Zhejiang Liangyi Valve Co., Ltd. official documentation